Cooling towers are differently designed by manufacturers and their structures may vary greatly in size and design, but the basic goal of each cooling tower is same. The function to dissipate waste heat from cooling tower is the sole thing that is included in each type of cooling tower. Talking in technical terms, every cooling tower, be it the industrial cooling tower or electrical cooling tower, is designed on the basis of specified cooling load that is expressed in refrigeration tons.

The cooling load is determined by the amount of heat that should be expelled from the cooling tower with the help of evaporation process. It must be rightly sized to reject the similar amount of heat in the air. Cooling towers are intended to reject heat via evaporation process. Warm re-circulating water is sent to the tower where a part of water is evaporated into the air through the tower. When the water evaporates, it lowers the temperature of the water present in the cooling tower.

The heat waste can be dissipated from the water to the air. Atmosphere having air with a lower humidity level has greater ability to absorb water via evaporation than air with extremely high humidity. It is because humidity level is lower in the air.

Cooling towers fall into two categories-

-

Open circuit – Open Circuit Cooling Tower has separate fluid circuits

-

Closed circuit – Closed Circuit Cooling Tower has no direct contact between the air and the fluid.

Open circuit cooling towers design returns the re-circulating water to the tower after absorbing the heat and distributes it throughout the tower. Closed circuit cooling tower is different as the water circulates through the structure in a coil, while cooling tower water re-circulates across the tower structure only.

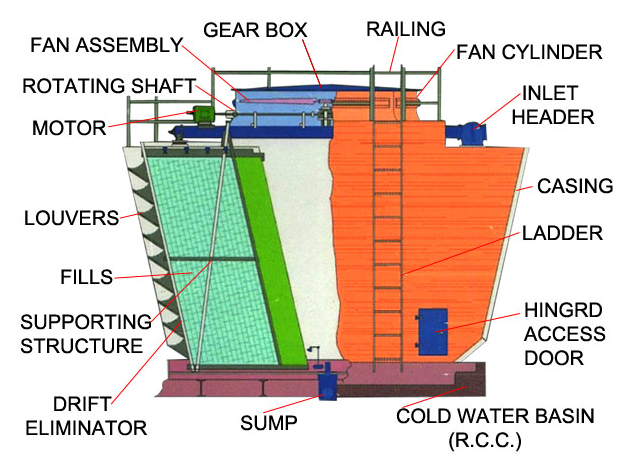

The structure

Cooling towers are the significant component used for treating heat in open recirculating model of cooling tower system. They are intentionally designed to maximize air and water contact in order to perform efficient evaporation process. This is acquired by maximizing the water surface area as it flows over and down via the tower structure.

The water in cooling tower is distributed evenly throughout the top of the cooling tower structure.

The older towers may have plastic, wooden, or FRP splash bars that serve to break the falling water into droplets or mist.

Do you know the terms used for cooling towers? Like blowdown, dissolved solids…

Blowdown -Water discharged to remove impurities, high mineral content, and debris.

Concentration cycles- It is the mass flow relationship between the feed water system amount and blowdown sent down the drain amount. High concentration cycles are directly related to low levels of water loss from the cooling tower system.

Dissolved solids – These are the dissolved minerals in the water content

Drift– These are water droplets entrained in the air, or blown from the tower side by crosswinds.

Make-up – It is the water supply required to replace all losses happen due to evaporation, discharge, or leaks in cooling towers.

So, in anyways, industrial cooling towers design solutions is precious to clients as it helps them in dissipating heat, treating waste heat and boost performance of the cooling tower and the applications connected to it.

Read more:

- Cooling Tower Exporters: A Source Of Foreign Exchange

- An Insight On Cooling Towers In India

- How Manufacturers Of Pultruded Cooling Towers Get More Business?